© Palladian Africa. Equipment shelters : Website design

Manufacturing Capabilities

Manufacturing Process

•

Customer inputs are considered integral throughout our manufacturing process.

•

Physical production commences on design acceptance and raw material buyout.

•

Quality Assurance is exercised at key holding points in the process and documented

accordingly.

•

Testing procedures are predefined and documented in the design phase and carried out and

recorded accordingly.

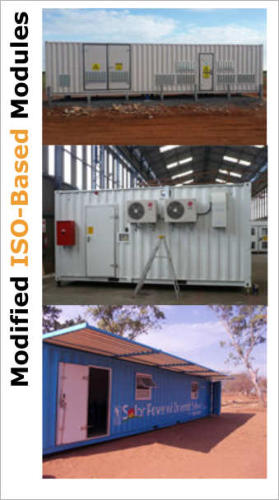

Raw Materials and Production

•

ISO Shipping containers are hand picked, single trip

shipping containers.

•

We only use the highest quality, approved materials.

•

Cutouts are done by plasma cutting and openings are

reinforced with steel frames.

•

Epoxy based direct to metal paint is applied to

specified thickness.

•

All components are manufactured on site by qualified

personnel and state of the art equipment.

•

Floor, wall and ceiling materials as well as doors,

cable entries and other peripheral fixtured are

installed.

Integration

We’ve inherently become specialists as integrators of

specified equipment - Salient and ancillary components

would vary based on the desired application as

illustrated (but not limited) to:

•

Electrical Distribution

•

HVAC Systems

•

UPS Systems

•

Generator Systems

•

Solar Power Systems

•

Access Control Systems

•

Fire detection and

suppression systems

•

Environmental Monitoring

Systems

•

Joinery Fittings

•

Furniture and Finishes

Click to zoom…

Click to zoom…

Click to zoom…

© Palladian Africa. Equipment shelters : Website design

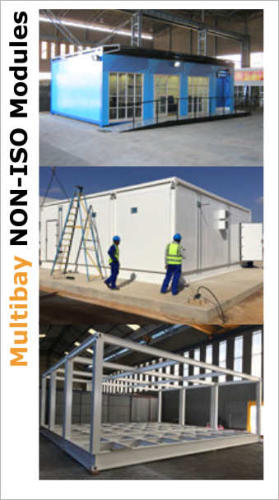

Equipment Shelters, Mobile Offices

Manufacturing Capabilities

•

Customer inputs are considered integral

throughout our manufacturing process.

•

Physical production commences on design

acceptance and raw material buyout.

•

Quality Assurance is exercised at key

holding points in the process and

documented accordingly.

•

Testing procedures are predefined and

documented in the design phase and

carried out and recorded accordingly.

Raw Materials and Production

•

ISO Shipping containers are hand picked,

single trip shipping containers.

•

We only use the highest quality, approved

materials.

•

Cutouts are done by plasma cutting and

openings are reinforced with steel frames.

•

Epoxy based direct to metal paint is

applied to specified thickness.

•

All components are manufactured on site

by qualified personnel and state of the art

equipment.

•

Floor, wall and ceiling materials as well as

doors, cable entries and other peripheral

fixtured are installed.

Integration

We’ve inherently become specialists as

integrators of specified equipment - Salient

and ancillary components would vary based on

the desired application as illustrated (but not

limited) to:

•

Electrical Distribution

•

HVAC Systems

•

UPS Systems

•

Generator Systems

•

Solar Power Systems

•

Access Control Systems

•

Fire detection and suppression systems

•

Environmental Monitoring Systems

•

Joinery Fittings

•

Furniture and Finishes

Palladian Projects africa

Palladian Projects

Tshwane, South Africa

Equipment Shelters, Mobile Offices

Full AC and DC Power Electrical Fitment

Customer Specials, Air Conditioning